The astronaut behind the rocket's "nerve center"

On October 31, the Mengtian Experimental Module soared into the sky under the support of the Long March 5 B Yao 4 carrier rocket. As the "nerve center" of the Wenchang Space Launch Site, the rocket control system team played an important role.

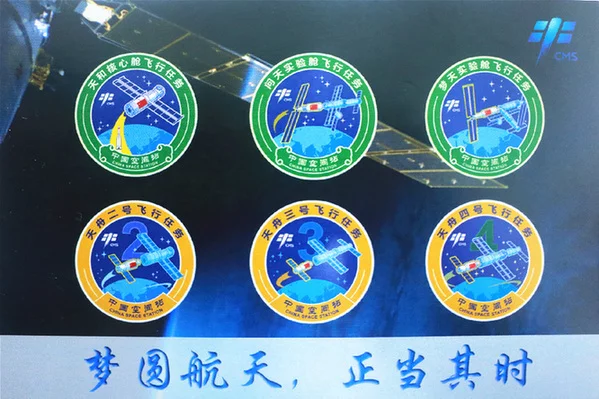

Wenchang Launch Site Space Station Construction Mission Promotional Card

"Zero window" ignition can not tolerate the slightest error

The rocket control system is known as the "nerve center" of the rocket. Its main function is to control the rocket to fly according to the predetermined trajectory and enter the orbit accurately. The control system team is responsible for the testing and launching of rocket instruments and equipment. Whether the performance and parameter status of these instruments and equipment are normal will directly affect the success or failure of the rocket's flight.

Yu Peng, the task leader of the control system, told reporters: "the dream sky cabin and the core cabin can be accurately docked under the condition of high-speed movement, and the ignition time error should be controlled within 1 second. This puts forward extremely high requirements for the operation of our control system before ignition. All test operations should be rapid and accurate, and no mistakes should be allowed."

In order to ensure the "zero window" ignition, Yin Jingbo, commander of the launch mission control system of the dream capsule, led the team to repeatedly refine the pre-launch process, making the pre-launch work accurate to minutes, minus 10 minutes or even seconds before launch, to ensure that every node and every operation before launch is precise and accurate.

Yin Jingbo and Yu Peng discuss problems in the test hall

Theory and practice must be closely integrated. Multi-round pre-launch process drills enable post personnel to master the timing of each password issuance and each operation content, and ensure that personnel can quickly interpret and feedback multiple 400 states and more than 2000 parameters.

"Golden Finger" Liu Qijie Observed and Recorded Test Parameters

What should I do if there is an accident? Deducting possible failures, they set more than 190 possible failure modes and formulated more than 410 disposal measures, all to ensure that the rocket can ignite on time.

Ten years of carrying a heavy load, just to fly

One minute on stage, ten years off stage. This ten-year foundation is the accumulation of this team by 1.1 points.

At the beginning of the construction of Wenchang launch site, the control system learned the theoretical knowledge of the control system, the new signal rocket technology theory, and the debugging and installation equipment again and again under the condition of "one poor and two white" in the construction of software conditions. With the spirit of hard struggle, the control system laid the foundation with nearly one million words of operating procedures and supporting teaching materials.

During the 908 days of carrying the load, the control system team quickly repacked and set off. Round after round of professional teaching, over and over again to improve the documents, over and over again to carry out exercises, independent design of circuit sand table, connector operation box, practice theory, practice operation, practice coordination, concentrate on foolproof preparation, with the ability of thick and thin hair, win the turnaround battle, honor battle, even if the long five-distance three tasks push again and again, it is difficult to stop their passion.

On-site teaching of control system personnel using circuit sand table

In the Spring Festival of 2020, the new crown epidemic raged and spread, nearly half of the post personnel can not return as scheduled, two first arrow missions in parallel, the epidemic brought inexplicable panic and other adverse factors in front of the control system.

Yin Jingbo, commander of the control system, recalled: "At that time, he was the" golden finger "of the first flight mission of Long March 5 B and the arrow operator of Long March 7 A. As soon as he finished working on one side, he quickly moved to the other side to carry out tests. The technical status of the two missions was different. Our system was" double thinking "and test preparation very late every night, all in order to ensure that the daytime test preparation was almost" white plus black."

March 2020 Changzheng No.7 A Star Arrow Combination Transition Site Slogan

Liao Guorui, commander of Mengtian capsule launch mission 01, told reporters: "At that time, I was in charge of the control system task. I was moved by the hard work of the staff in the post and the dedication of many people who had been riveted in the post for nearly 90 days."

Day and Core Module Mission Control System Pledge Mobilization

This was the firm belief and concerted action of the control system team at that time. Through this process of overcoming the difficulties, the control system team's comprehensive test and hair ability has been significantly matured and improved, laying a solid foundation for the follow-up mission Lien Chan's winning streak.

Road resistance and long, Yi Jian

When it is difficult, it shows courage and perseverance, and when it is honed, it becomes jade.

In 2021, after the Tianzhou-2 mission was suspended twice, the propellant was drained back and refilled twice. All the scientific and technical personnel of the test and development team shouted the battle slogan of "do whatever it takes for the mission, do not hesitate for the mission", and staged a mission relay that raced against time and competed with problems.

The personnel of the control system always kept awake, maintained their concentration, stabilized their minds and feet, cooperated with all systems, worked together in the same boat, overcame the difficulties together, and finally wrote a new miracle of aerospace with success.

Tianzhou 2 Control System Commander Zhang Bo

The high-density mission in 2022 made time pass quickly. After the successful launch of the "Ask the Sky" module, it was too late to rest and put into the 90 days when the three missions of "Zhongxing", "Dream Sky Module" and "Tianzhou 5" were intertwined and parallel. For the young team, this "ultra-high density" had never been experienced before. It also coincided with the severe epidemic situation in Hainan, the adverse effects of personnel fatigue and static control, which once again tested them.

The control system team deeply understood the "great significance and extraordinary mission" of the space station construction task, maintained the determination of "steady and steady", established the belief in victory, firmly dared to fight, overcome the pressure of continuous high-density tasks, overcome the impact of static control, and fought continuously and under pressure, fully demonstrating the excellent style of "taking responsibility before the war.

Control System Technologists Participate in Mengtian Experimental Module Transfer Activities

The control system personnel voluntarily gave up the rest to accompany their wives and children, riveted in their posts for nearly 30 days and worked overtime in order to master the test status and process more accurately.

Sun Jing, head of the servo mechanism responsible for the two types of rockets, is in the lactation period. He takes care of the children and puts more energy into the task.

Dou Tianheng, who is also the third post, Hao Jianjun, who postponed the wedding date, Wang Buhua's family with two children alone ...... and so on, each comrade is using action to explain the dedication of the small family to the overall situation.

Check the test status of the post personnel on the control system arrow

Although ordinary, unknown, but their cause is great.

Although they were miserable and slept at night, they were happy with it.

Although it is difficult and heavy to carry forward, they lift the weight lightly.

All because the belief of "space power" and "space serving the country" has long been integrated into the blood, forming the "winning gene" for building a world-class space launch site and building a space power ".

(The manuscript was jointly planned by Xinhua and Wenchang Space Launch Site)

Responsible editor: You Yuan Yuan Yuan_1000